Introduction

In today’s fast-evolving digital and industrial landscape, new technologies, platforms, and material-related solutions frequently emerge, each aiming to solve specific problems or improve efficiency. One such term that has recently started gaining attention online is Chromtex. Many users are searching for answers to questions like What is Chromtex?, How does Chromtex work?, and What are the real uses and benefits of Chromtex?

This article provides a complete, in-depth, and purely informational guide to Chromtex. The goal is to explain the concept clearly, explore its features, outline its possible uses, and highlight its benefits in a simple, human-readable way. Whether you are a beginner, a researcher, or someone exploring Chromtex for professional reasons, this guide will help you understand it without confusion or thin content.

What Is Chromtex?

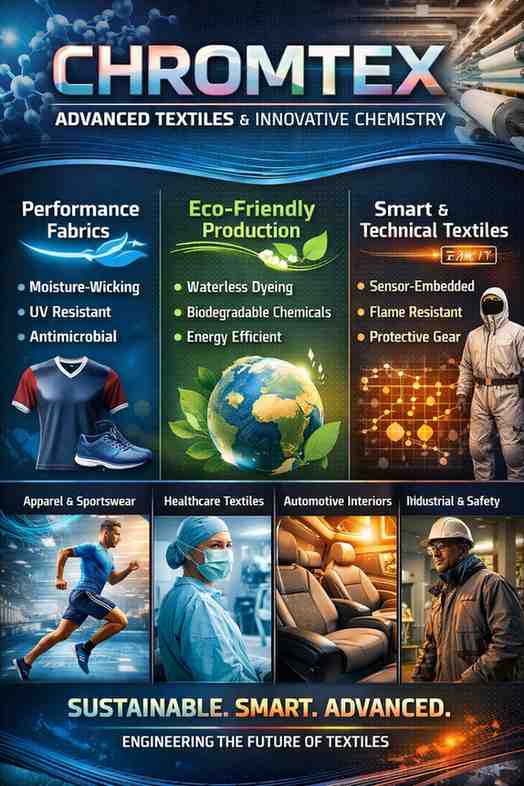

Chromtex is a term commonly used to describe a specialized technology, material system, or platform associated with advanced surface treatment, coating solutions, or digital-industrial applications, depending on its context of use. While the exact definition of Chromtex can vary by industry, it generally relates to enhancing performance, durability, appearance, or efficiency through innovative processes.

In many cases, Chromtex is associated with chromium-based technologies or advanced textile and surface engineering concepts, combining strength, resistance, and adaptability. It may be referenced in industrial manufacturing, material science, or digital branding environments where durability and quality are essential.

Rather than being a single product, Chromtex often represents a concept, system, or solution framework designed to meet modern technical and industrial demands.

Understanding the Concept Behind Chromtex

To fully understand Chromtex, it helps to break the term into two conceptual parts:

- “Chrom” – Often linked with chromium, color enhancement, strength, corrosion resistance, or high-performance surfaces.

- “Tex” – Commonly associated with textiles, textures, technology, or technical systems.

When combined, Chromtex typically refers to a solution that integrates strength, visual appeal, and performance, whether in physical materials or technology-driven systems. This combination makes it relevant across multiple sectors.

Key Features of Chromtex

Chromtex is valued for a set of core features that make it attractive in both industrial and technical contexts. Below are some of the most commonly associated features.

1. Enhanced Durability

One of the primary features of Chromtex-related solutions is high durability. Materials or systems under the Chromtex concept are often designed to withstand wear, pressure, environmental exposure, and long-term usage.

2. Corrosion and Damage Resistance

Chromtex is frequently linked with resistance to corrosion, moisture, heat, and chemical damage. This makes it suitable for demanding environments where standard materials or systems may fail.

3. Advanced Surface Quality

Another notable feature is improved surface quality, which can include smoother finishes, better texture control, or enhanced visual appearance. This is especially important in industries where both function and aesthetics matter.

4. Adaptability Across Industries

Chromtex solutions are often designed to be flexible and adaptable, allowing them to be used in manufacturing, textiles, construction, automotive, or even digital branding and technology systems.

5. Modern Technology Integration

In some contexts, Chromtex also represents technology-driven processes, integrating automation, precision control, or data-driven optimization to improve overall performance.

How Does Chromtex Work?

The working mechanism of Chromtex depends on its application area. However, the general process follows a structured approach:

- Material or System Selection – Choosing the base material, surface, or platform where Chromtex principles will be applied.

- Treatment or Enhancement Process – Applying coatings, treatments, or technical modifications to enhance performance.

- Quality Optimization – Improving resistance, strength, or appearance through controlled processes.

- Testing and Validation – Ensuring the final output meets durability and performance standards.

This systematic approach allows Chromtex-based solutions to deliver consistent and reliable results.

Common Uses of Chromtex

Chromtex is not limited to a single use case. Below are some of the most common areas where Chromtex-related concepts are applied.

Industrial Manufacturing

In manufacturing, Chromtex is often linked with surface protection, component durability, and performance enhancement. It helps machinery parts last longer and perform more efficiently.

Textile and Fabric Applications

In textile-related contexts, Chromtex may refer to treated or engineered fabrics that offer improved strength, resistance, or texture quality compared to traditional textiles.

Automotive and Engineering

Chromtex concepts are useful in automotive and mechanical engineering, where resistance to heat, friction, and corrosion is critical for safety and longevity.

Construction and Infrastructure

In construction, Chromtex-inspired solutions may be used to enhance structural components, coatings, or finishes, improving durability and reducing maintenance needs.

Technology and Branding

In digital or brand-related contexts, Chromtex may also be used as a technology or product identity, representing innovation, reliability, and modern design.

Benefits of Chromtex

Chromtex offers several practical benefits that make it valuable across industries.

Long-Term Cost Efficiency

Due to its durability and resistance, Chromtex-based solutions often reduce maintenance and replacement costs over time.

Improved Performance

Enhanced material strength and system efficiency lead to better overall performance, especially in demanding environments.

Aesthetic and Functional Balance

Chromtex provides a balance between visual appeal and functionality, making it suitable for both visible and technical applications.

Reliability and Consistency

Systems or materials developed under Chromtex principles are designed for consistent results, reducing the risk of failure.

Versatility

The adaptability of Chromtex allows it to be used across multiple industries without losing relevance or effectiveness.

Is Chromtex Environmentally Friendly?

Environmental impact depends on how Chromtex is implemented. Modern Chromtex-related technologies often aim to:

- Reduce waste through longer-lasting materials

- Improve efficiency to lower resource consumption

- Support sustainable manufacturing practices

When applied responsibly, Chromtex can align with eco-conscious and sustainability goals.

Who Should Consider Using Chromtex?

Chromtex may be suitable for:

- Manufacturers seeking durable solutions

- Engineers looking for performance-enhancing materials

- Businesses focused on long-term efficiency

- Designers who need both strength and aesthetics

- Researchers exploring advanced material systems

Future Potential of Chromtex

As technology and material science continue to evolve, Chromtex is expected to expand further. Innovations may include:

- Smarter material integration

- Improved sustainability standards

- Wider adoption across industries

- Enhanced customization options

The future of Chromtex appears promising as industries demand more reliable and efficient solutions.

Conclusion

Chromtex represents a modern, adaptable, and performance-focused concept that combines durability, efficiency, and advanced technology. Whether applied in manufacturing, textiles, construction, or technology-driven systems, Chromtex offers clear benefits that go beyond basic solutions.

By understanding what Chromtex is, how it works, and where it can be used, individuals and businesses can make informed decisions without relying on thin or misleading information. As industries continue to prioritize quality and sustainability, Chromtex is likely to remain a relevant and valuable solution in the years ahead.